The quality department is divided in two sections:

Materials checking Section

The material checking section is responsible to follow the metallurgical tests on the raw material and the individual components.

- Destructive tests with execution of micrographs, macrographs and control of the chemical composition of the material

- Non-destructive testing: by means of ultrasonic, liquid penetrant, micro- hardness measurements and magnetic particle inspections.

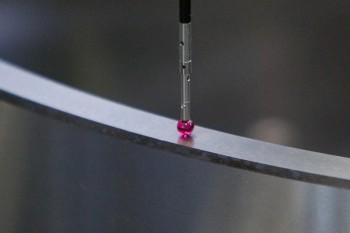

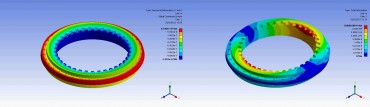

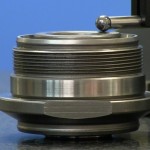

Testing Section

The testing section, following the procedures outlined in the Quality Manual, is responsible for performing geometric and dimensional checks during all phases of the production cycle.

The calibration of measuring instruments to carry out the checks, is performed with the aid of a calibration bench SIT.